Product overview:

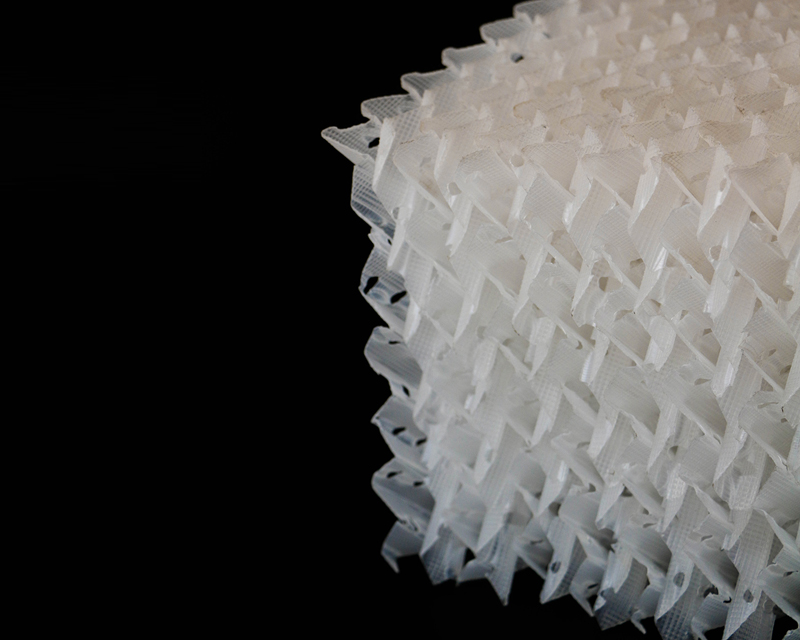

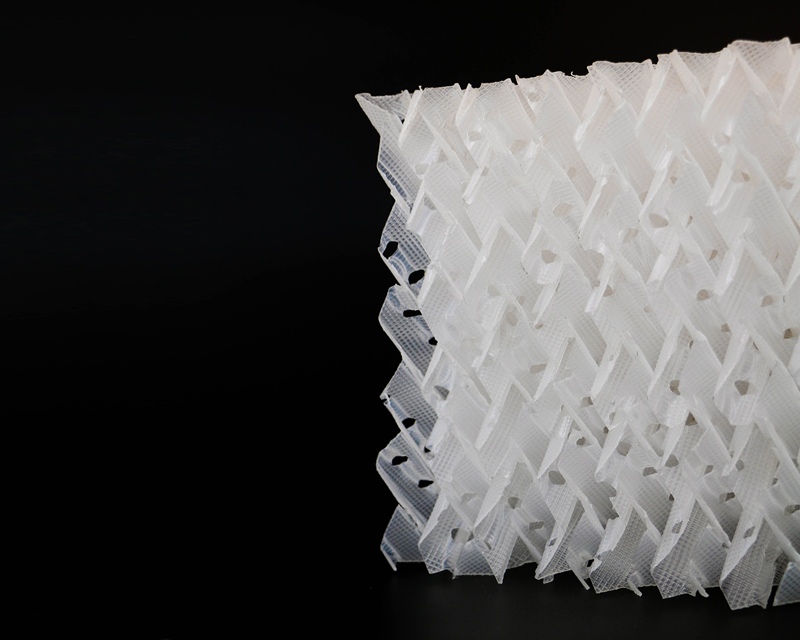

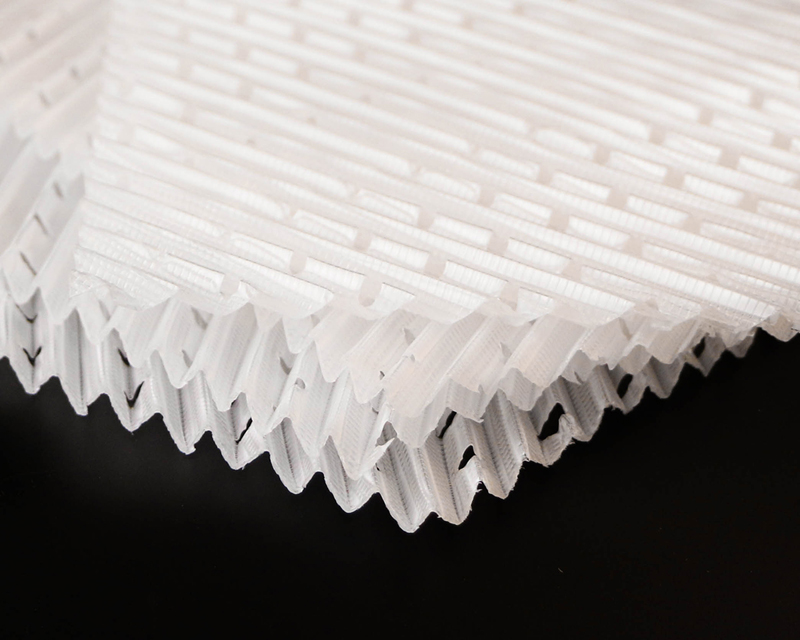

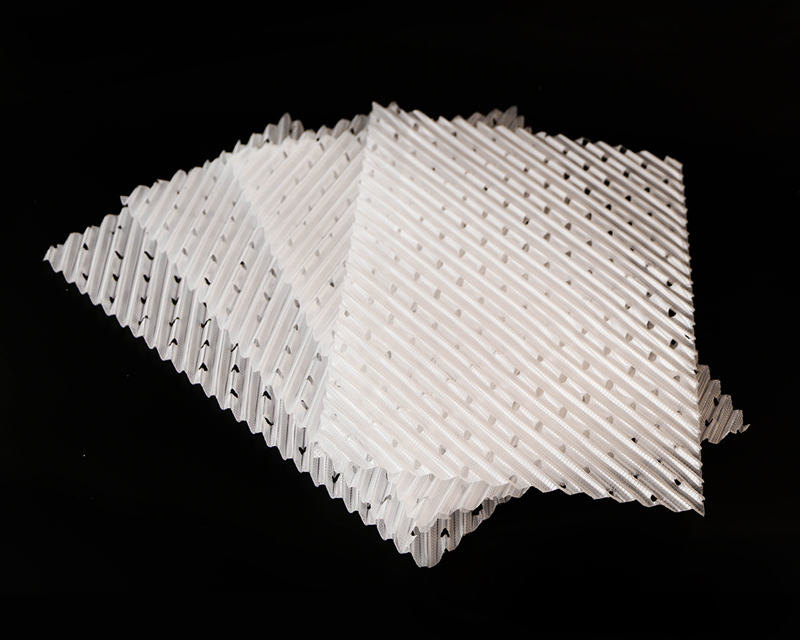

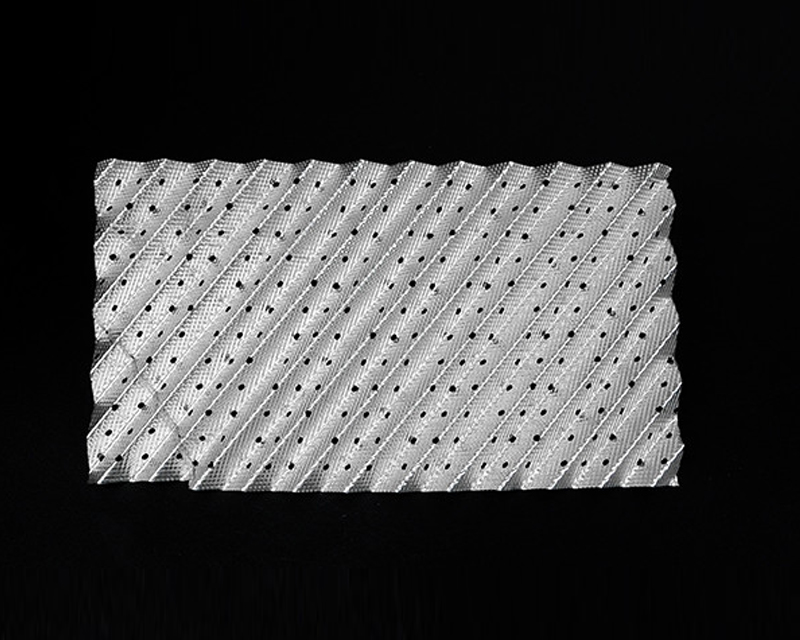

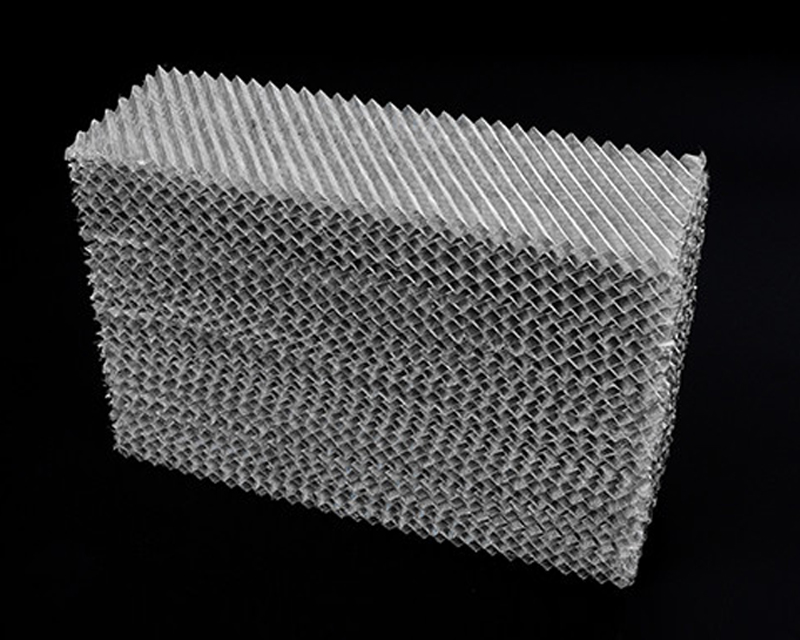

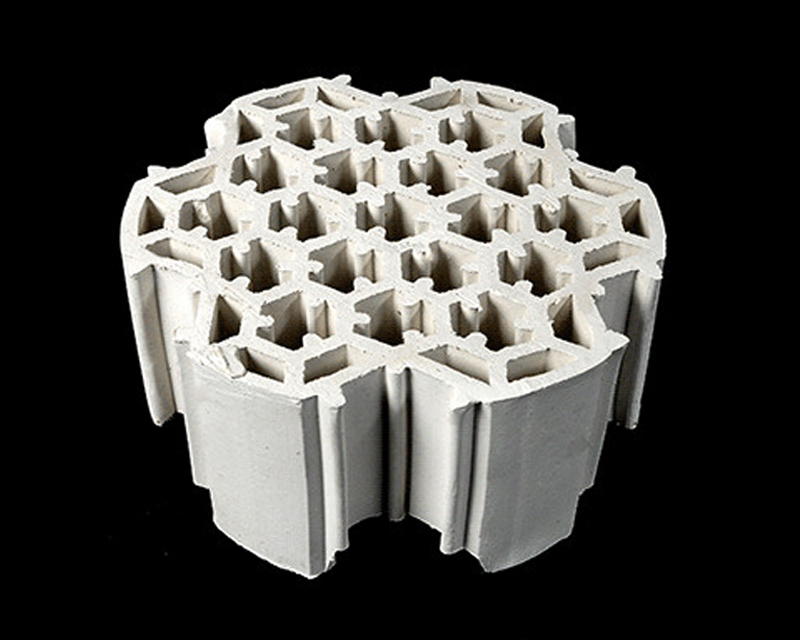

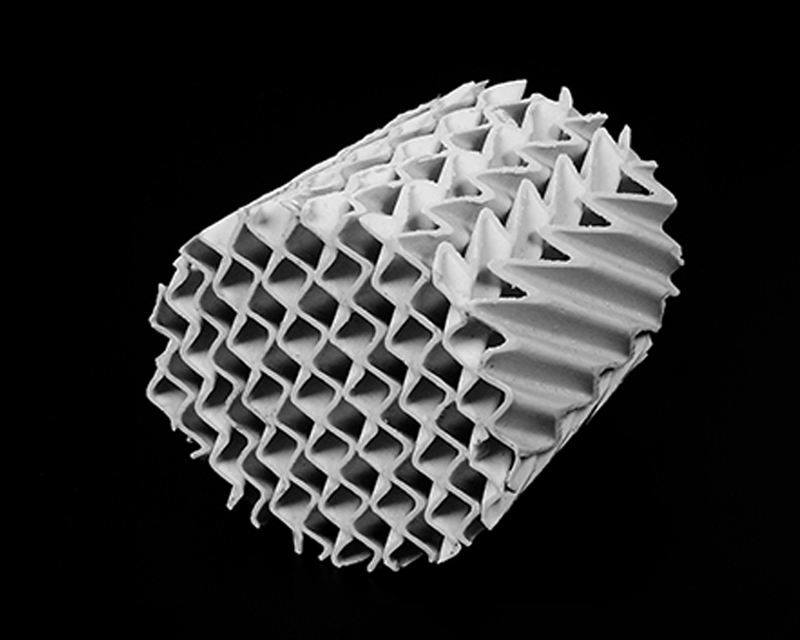

Plastic corrugated board packing has the advantages of light specific gravity, high capacity, reduced pressure, large specific surface area, and easy replacement. It is widely used in unit operations like distillation, absorption and extraction. The heat resistance of the material reaches 100°C for PP and 150°C for PVDF. There will be small holes and perforations on the surface of the packing to improve the mass transfer efficiency. If the separation requirement is not high, it does not need perforation, so the strength of the board will increase.

The product mainly includes PP, PE, PVDF, PVC, RPVC, RPP, material

Product Features:

● Plastic orifice corrugated packing can be operated under negative pressure and pressure, and its mass transfer performance is also more than 50% higher than that of the medium 50m Pall ring. The main advantages of plastic orifice corrugated packing are corrosion resistance, light weight and low price. Due to its large flux, low pressure drop, and high specific surface area, it has greater advantages in expanding production, expanding the scope of use, reducing energy consumption, and improving efficiency. At present, it is widely used in various absorption and desorption operations, especially suitable for large liquid load and high operating pressure processes. For the hydrochloric acid and sulfuric acid industry, the removal of c2 and h-s in natural gas, the preparation of ammonia liquid, various waste gas purification treatment and desorption and degassing devices. It is widely used in oil refining, crude oil processing, petrochemical industry, gas purification, chemical fertilizer, environmental protection (especially in ammonia desulfurization), fertilizer plant desulfurization tower, metallurgy, steel and other industries.

|

Model

|

Specific surface area

|

Porosity

|

Pressure drop

|

Bulk weight

|

Packing factor

|

|

SB-125Y

|

125

|

98

|

200

|

45

|

3

|

|

SB-250Y

|

250

|

97

|

300

|

60

|

2.6

|

|

SB-350Y

|

350

|

94

|

200

|

80

|

2

|

|

SB-500Y

|

500

|

92

|

300

|

130

|

1.8

|

|

SB-125X

|

125

|

98

|

140

|

40

|

3.5

|

English

English Chinese

Chinese