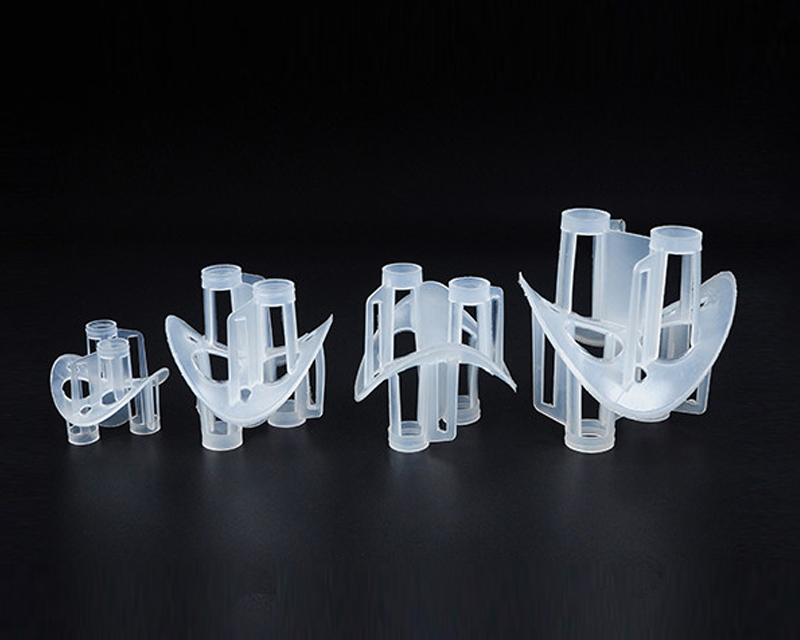

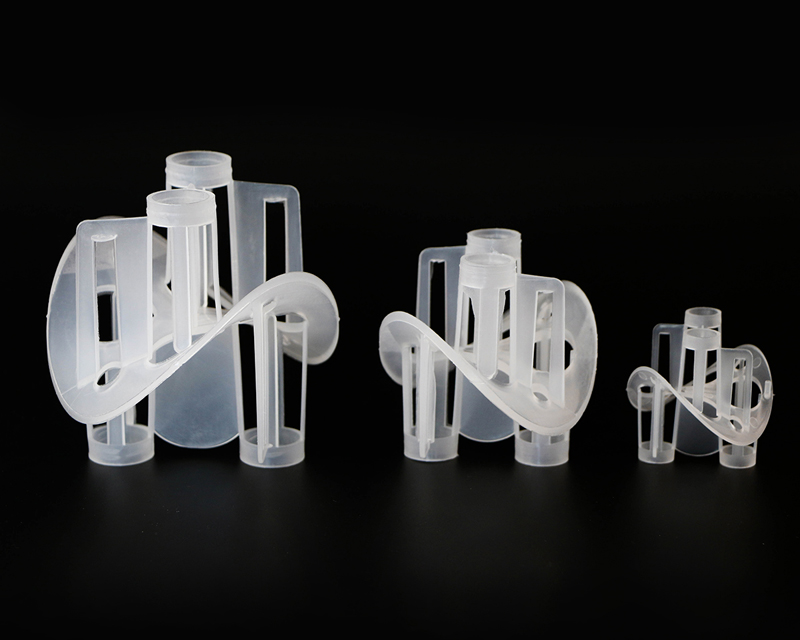

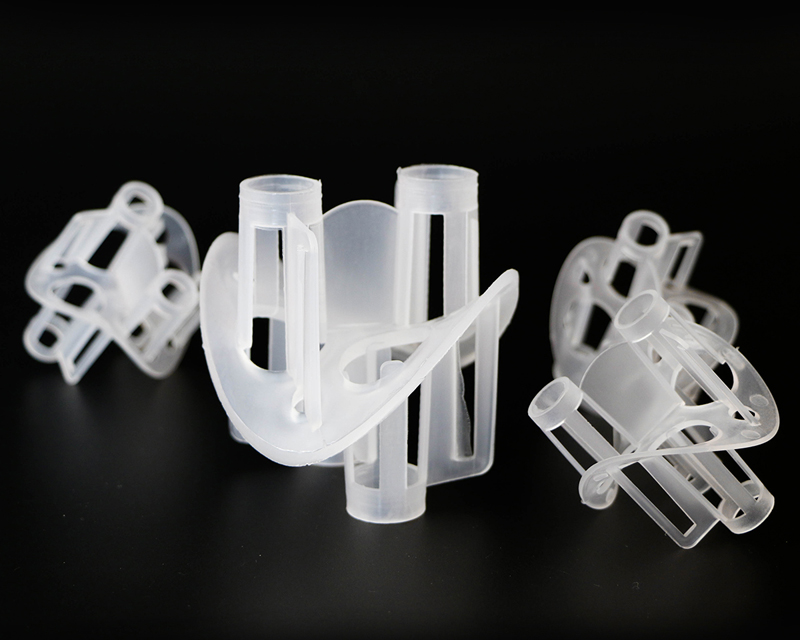

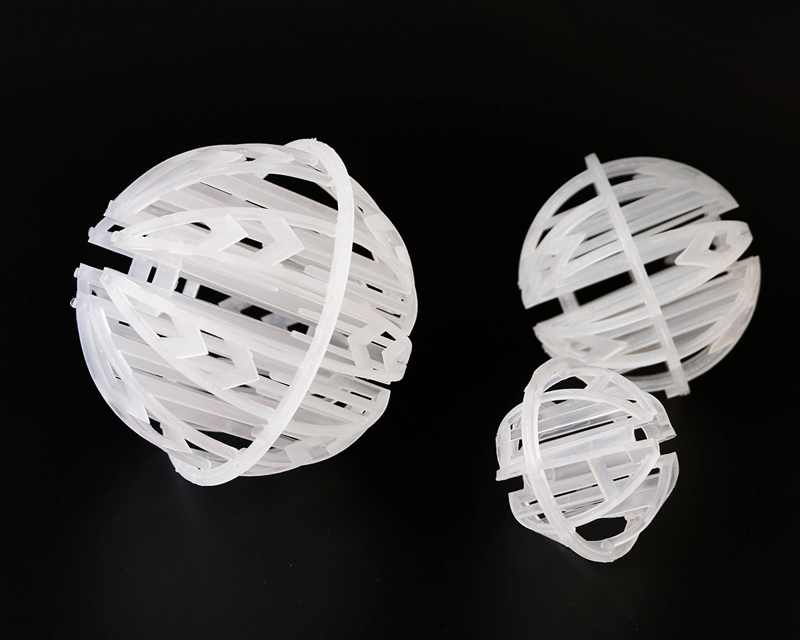

Product overview:

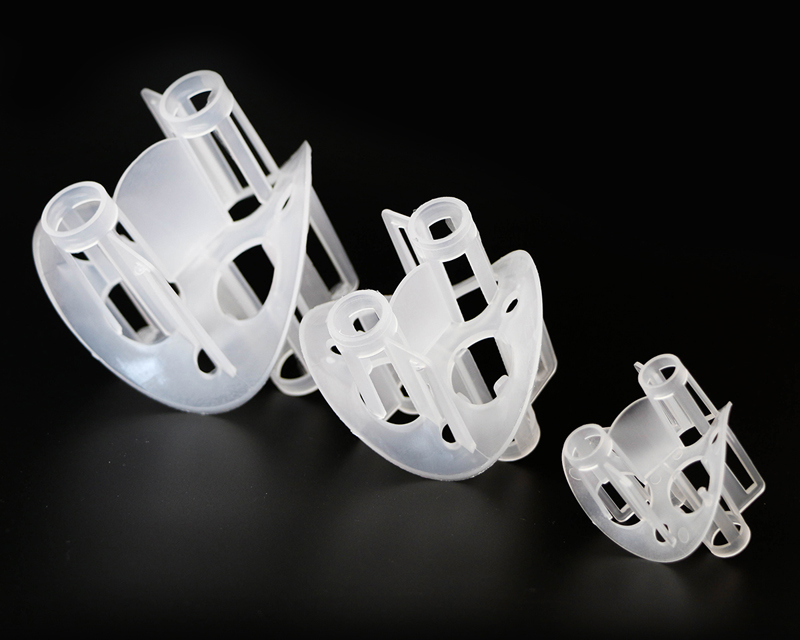

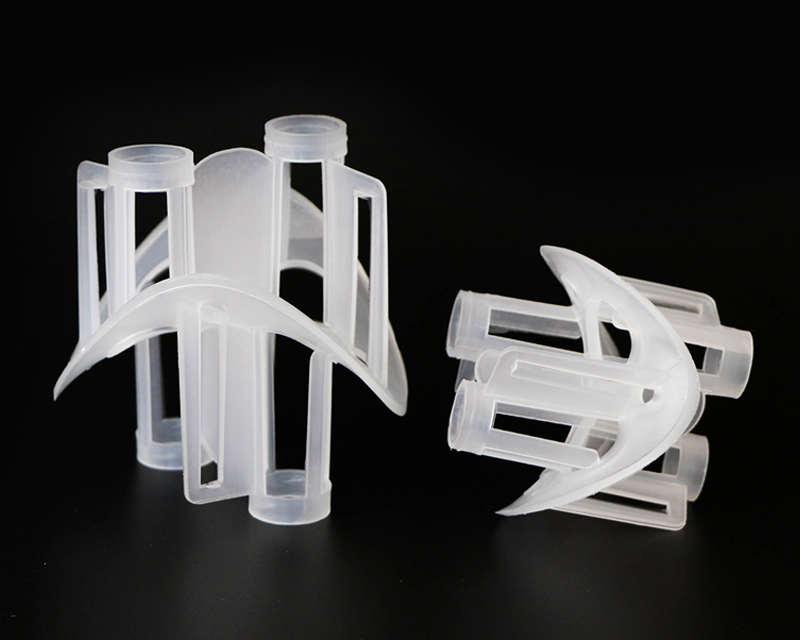

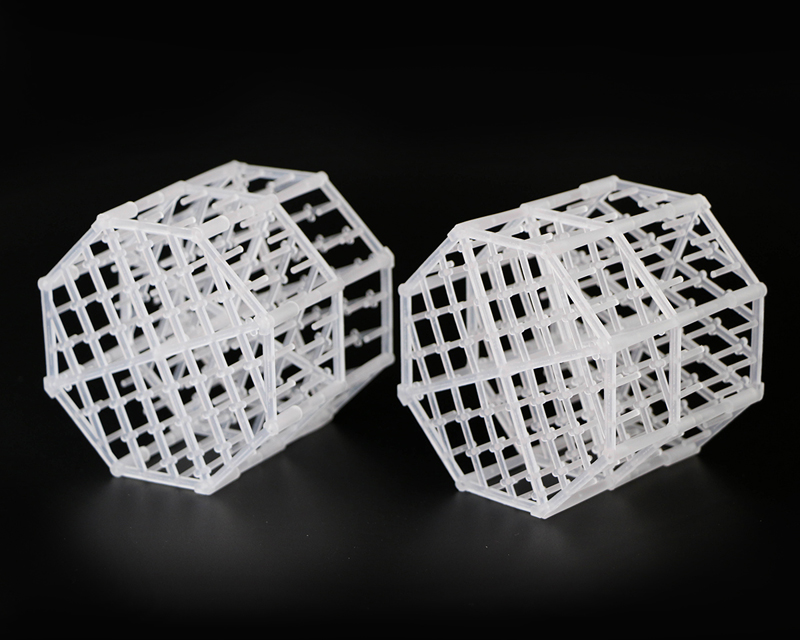

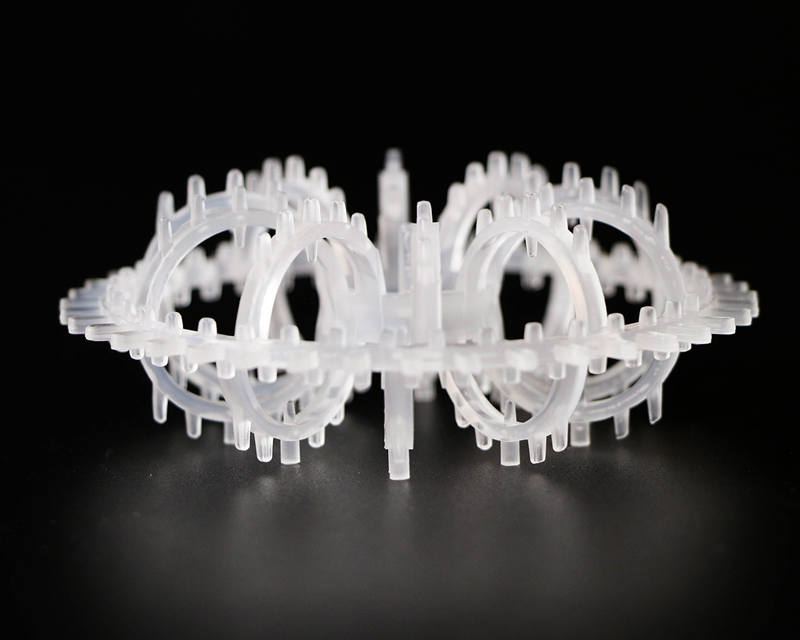

Plastic Haier ring packing is a new type of open-cell packing made of polypropylene injection molding, which has long been developed abroad. Later, our country conducted research on this kind of packing, and successfully developed the domestic Haier ring packing.

Product Features:

●The unique shape of Haier ring makes it not only has the advantages of large flux, pressure drop, corrosion resistance and good impact resistance, but also has the advantages of no nesting between fillers, small wall flow effect and uniform gas-liquid distribution.

●This packing is suitable for processes such as gas absorption, cooling and gas purification. The plastic Haier ring is a new type of open-cell filler with a unique structure. It is usually made of polypropylene by injection molding. Its large specific surface area and porosity help to improve the performance of the product.

|

Product name

|

Plastic Haier Ring

|

|

Material

|

PP, RPP, PE, PVC, CPVC, PVDF, PTFE

|

|

Service life

|

3 years

|

|

Size mm

|

Specific surface area m2/m3

|

Porosity%

|

Pieces/m3

|

Bulk weight Kg/m3

|

Dry packing factor m-1

|

|

50

|

107

|

94

|

8000

|

50

|

128

|

|

76

|

75

|

95

|

3420

|

45

|

87

|

|

100

|

55

|

96

|

1850

|

48

|

62

|

|

Performance

|

Large porosity, low pressure, low mass transfer unit height, high flooding point, sufficient gas-liquid contact, small specific gravity, high mass transfer efficiency

|

|

Advantages

|

1. The special structure enables large circulation, lower pressure and good mechanical strength.

2. Strong corrosion resistance, large porosity, energy saving and environmental protection, low cost, light specific gravity, easy to load and unload.

|

|

Application field

|

Gas absorption, acid gas adsorption system, scrubber, fertilizer production. Used in gas absorption tower, acid gas adsorption system, fertilizer production. The maximum operating temperature of plastic random packing is 280 degrees Celsius, and it is widely used in packing towers in petroleum, chemical, chlor-alkali, gas, and environmental protection industries.

|

|

Properties/Materials

|

PE

|

PP

|

RPP

|

PVC

|

CPVC

|

PVDF

|

|

Density (after injection)

|

0.98

|

0.96

|

1.2

|

1.7

|

1.8

|

1.8

|

|

Operating temperature

|

90

|

>100

|

>120

|

>60

|

>90

|

>150

|

|

Corrosion resistance

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

GOOD

|

|

Compressive strength

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

>6.0

|

English

English Chinese

Chinese